Client Inquiry

I lead AI strategy for the supply chain organization at my company. I need concrete examples of how other enterprises are using AI to address real supply chain problems. We manage a massive portfolio of SKUs across multiple channels, and accuracy in forecasting, sourcing, and delivery directly affects customer satisfaction and operational performance. I want to understand how other organizations are applying machine learning, generative AI, and agentic approaches to issues like supplier performance, catalog alignment, logistics delays, and real-time decision making. My goal is to identify practical use cases and patterns that can inform our roadmap.

Expert Takeaways:

1. Strong architectural foundations accelerate every supply chain AI initiative

When the underlying architecture is clean and consistent, AI teams can move quickly across merchandising, sourcing, catalog alignment, and logistics. A unified cloud environment, shared data structures, and well-defined interfaces reduce the friction that normally slows supply chain experimentation. Once data is organized and pipelines follow consistent patterns, teams can deploy forecasting and optimization models without reengineering the environment each time.

Key Insights:

- Unified cloud environments support fast iteration and easier deployment

- Stable data structures enable reuse across inventory, sourcing, and logistics models

- Clear architecture reduces the burden on downstream engineering teams

- Consistency allows small teams to deliver impact across multiple supply chain domains

- Foundations determine the speed at which new AI use cases can be added

2. Predictive models reshape merchandising and sourcing decisions

Forecasting and sourcing models create measurable improvements in delivery accuracy and profitability. These models evaluate historical demand, channel expectations, supplier reliability, distance, shipping costs, and margins to determine what should be surfaced on each marketplace and who should fulfill each order. This allows companies to commit to fast delivery windows without stocking every item themselves.

Key Insights:

- Merchandising models decide what to show on Amazon, Walmart, and other channels

- Sourcing algorithms optimize for speed, margin, distance, and delivery reliability

- Forecasting accuracy directly improves customer experience and on-time delivery

- Modeling demand helps shape purchasing behavior, not just react to it

- Supplier performance models improve fulfillment decisions at scale

3. Generative AI improves catalog accuracy and reduces downstream defects

Supplier-provided product data often arrives incomplete, inconsistent, or incorrectly structured. Generative AI and matching models can map these feeds to internal SKUs, surface missing attributes, and flag suspicious records for review. Better catalog alignment reduces customer returns, improves listing quality, and accelerates time-to-market for new products.

Key Insights:

- AI matches messy supplier data to internal SKUs with higher accuracy

- Missing fields are filled or identified early to prevent defects

- Cleaner catalogs reduce operational friction across the supply chain

- Feedback loops continually improve the mapping model

- Significant value appears when many suppliers send heterogeneous data

4. Delivery prediction models provide early warnings for shipping delays

Carrier networks are opaque, but shipment patterns create enough signal to predict when deliveries will miss promised dates. Logistics prediction models estimate routing through specific hubs, the likelihood of delay at each stage, and the probability of late delivery. These early indicators allow supply chain teams to intervene before the customer is affected.

- Hub-level routing predictions help anticipate delays before they occur

- Early warnings enable proactive outreach and corrective action

- Even partial prediction accuracy reduces customer service incidents

- Models operate on internal data without relying on carrier APIs

- Delivery promise accuracy improves when predictions inform fulfillment

5. AI delivers the most value when strategy, operations, and leadership stay aligned

Supply chain AI works when teams share a clear, connected view of how forecasting influences sourcing, how sourcing affects fulfillment, and how delivery performance shapes customer trust. Alignment across business leaders, architects, operators, and analysts ensures that AI solves real bottlenecks instead of isolated technical problems. When strategy is clear, the roadmap becomes easier to prioritize and adoption moves faster.

Key Insights:

- Alignment directs AI toward the most operationally meaningful problems

- Shared goals keep forecasting, sourcing, and logistics coordinated

- Leadership clarity accelerates cross-functional adoption

- Fragmented priorities slow down even the best technical teams

- Transformation succeeds when AI is tied to the full supply chain value stream

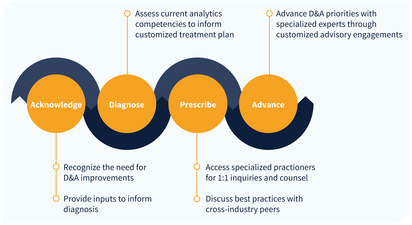

Expert Network

IIA provides guided access to our network of over 150 analytics thought leaders, practitioners, executives, data scientists, data engineers with curated, facilitated 1-on-1 interactions.

- Tailored support to address YOUR specific initiatives, projects and problems

- High-touch onboarding to curate 1-on-1 access to most relevant experts

- On-demand inquiry support

- Plan validation and ongoing guidance to advance analytics priority outcomes

- Monthly roundtables facilitated by IIA experts on the latest analytics trends and developments